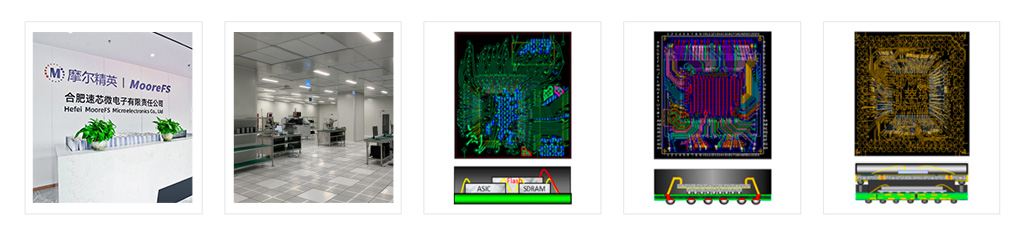

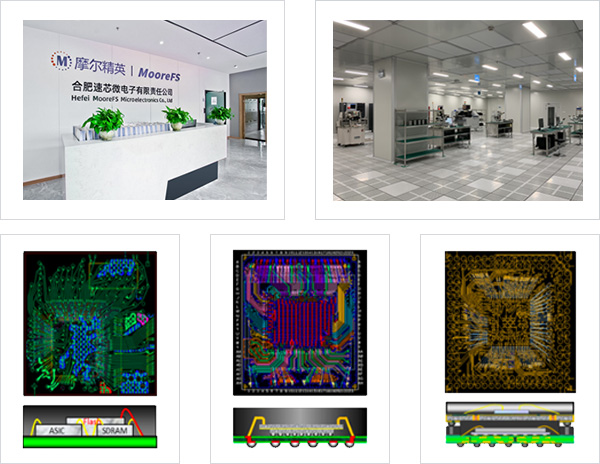

Assembly Service

Introduction

MooreElite Chip Packaging Service: with our own fast-packaging factory, we provide high-quality and efficient fast packaging service in the product development stage. Relying on the long-term cooperation with mainstream packaging factories at home and abroad, we provide customers with one-stop chip packaging services, and guarantee delivery, production capacity and quality in the packaging stage for our customers. We provide one-stop SiP service of design, simulation, proofing, and mass production.We also provide rich bare die resources, experienced solution development and SiP design teams, fast and efficient proofing factories and first-class mass production packaging resources.

Service List

Fast packaging

Fast and engineering packaging, we have our own fast packaging line in Hefei, with a monthly production capacity of 1KK, which can meet the engineering and fast packaging needs of customers. A second fast packaging line will be built in Chongqing next year.

Business status: There are nearly 400 trading customers, and 300+ batches of fast packaging and engineering batch output per month.

Business status: There are nearly 400 trading customers, and 300+ batches of fast packaging and engineering batch output per month.

Mass packaging

The mass production business adopts the “Meituan plus service model”, not only placing orders on an agent, but also providing customer with packaging design, yield monitoring, quality monitoring, delivery follow-up, material stocking, and quality exception handling. When customers enter the mass production stage, they will place orders to ASE/Amko/Tongfu/Jiangdian/Huatian and other large factories (the cost-effectiveness is better than the customer’s own contact).At the same time, we provide the above services without extra cost. Due to the long-term cooperation with major packaging manufacturers, we have greater influence on capacuty. If customers need, we can also recommend many low-cost factories.

Business status: mass production customers have reached 53, with shipments reaching 63.5kk/month in October.

SiP package design and production

MooreElite provides SiP services of solution development, substrate design, simulation, proofing and mass production. MooreElite has rich bare-die resources, more than 25 years of experience in the solution development engineering team, 17 years of experience in the SiP design team, more than 50 SiP mass production solutions, the world’s top three packaging resources. MooreElite is a qualified supplier of CRRC and the partner of Bosch, Didi(driveless technology) and top domestic universities and research institutes.

Strength

Fast packaging

- Engineer team with an average of 10.8 years of working experience (> 5 yrs ASE working experience)

- High-standard workshops at international level

- Mainstream equipment in the industry

- Engineering packaging with short period(< 7 days ), competitive cost, complete packaging type support

Mass packaging

- Guaranteed production capacity

- Trusted partners (ASE, Amkor, TF, JCET.etc)

- Optimized practice

- Deliver over 10M chip per month

SiP package design and production

- Rich SiP design experience

- Over 50 SiP chip design delivered

- Deliver 2M SiP chip per month

- Comprehensive bare-die sourcing (Mem, RF, PMIC, MCU)

Successful Cases

| Application | Bare Die Package | Advantages | Volume |

| Remote control | MCU、RF transceiver modules SiP package | Compared to SoC,cost down 60%; shorten develop cycle(by 1 month),expedite time to market | 1.0kk/month |

| Security | MCU、Bluetooth、BLE、passives SiP package | Compared to system board, much less area (85% reduction), easy installation and better reliability | 1.5kk/month |

| NB-IoT | NB-IoT、Flash SiP package | Compared to eFlash SoC,lower cost and higher yield | 200k/month |

| MCU | 32bit M4 MCU 、Flash SiP package | Compared to eFlash SoC,lower cost and higher yield | 600k/month |

| Smart Robotics | Image processing, MCU SiP package | Compared to eFlash SoC,lower cost and higher yield | 200k/month |

| 3D deep learning | 3D sensor、3D ASIC SiP package | Small size and high performance to price ratio | 200k/month |